Bob Barauskas from Speonk Lumber stopped by the site while I was there on Thursday. He had come over to take a look at the ZIP System sheathing that the framing crew had started to install earlier in the day. Bob wanted to confirm that the pieces that Speonk had delivered to us had come from Huber Engineered Woods' Crystal Hill, Virginia mill.

Bob Barauskas of Speonk Lumber at the Sunset Green Home project site

Why is the facility location important to the Sunset Green Home project?

LEED for Homes rewards projects that use components that are "extracted, processed and manufactured within 500 miles of the home." The LEED for Homes rating system explains, "a substantial amount of energy is used to transport materials from product manufacturing plants to home construction sites. Choosing local products will reduce the embedded transportation energy usage associated with construction."

As long as 90% of a product complies with the 500 mile regional production requirement, it can receive the credit.

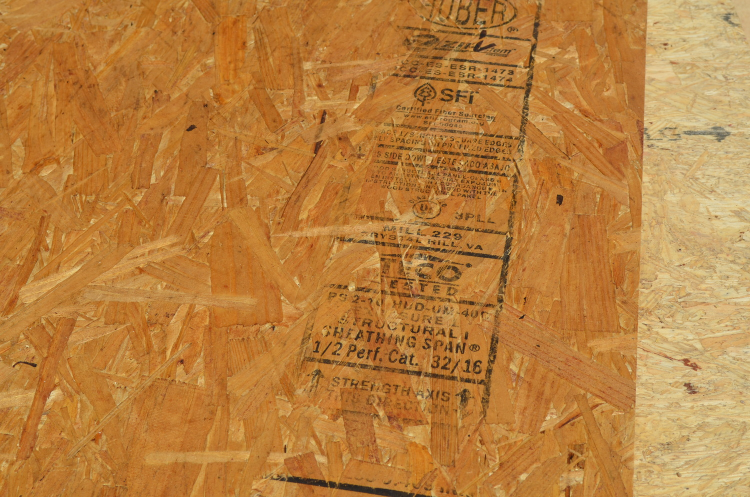

ZIP System panel marked with the Crystal Hill, Virgina mill's identifying information

Sunset Green Home is using ZIP Systems for all wall and roof sheathing. The product is manufactured in two locations, each within close proximity to the forests from which the raw materials are harvested. However, only the Crystal Hill, Virginia location and the local forest where it sources its wood are less than 500 miles from the Sunset Green Home project site. So, in order to receive the credits, we need to verify that we're receiving products from the Crystal Hill facility. Each of the ZIP System panels is stamped with the location of the mill that produced it. In our case, Bob was able to visually verify that we received the right materials.

Many of us are aware of where our food comes from. And we choose to buy locally grown fruits and vegetables to support local agriculture and reduce carbon emissions that arise from transporting the produce. LEED is trying to build the same awareness within the building sector.

We are planning to use as many local or regional materials as we can on the Sunset Green Home project, in order to minimize the embedded transportation energy embodied within the products. Already, as I mentioned in an earlier post, we have included foundation pilings that were sourced from a forest in Maryland. And now, with the ZIP System products, we've added a second regional product. We've been investigating options for hardwood flooring that will be regionally sourced as well. We have so many wonderful materials available just within reach. Why not do what's best for the environment, what minimizes our transportation costs, and what allows us to earn LEED for Homes credits at the same time!

Get to know LEED...so you can adopt some of these sensible building practices.